Products

Home - Products - PU Pouring

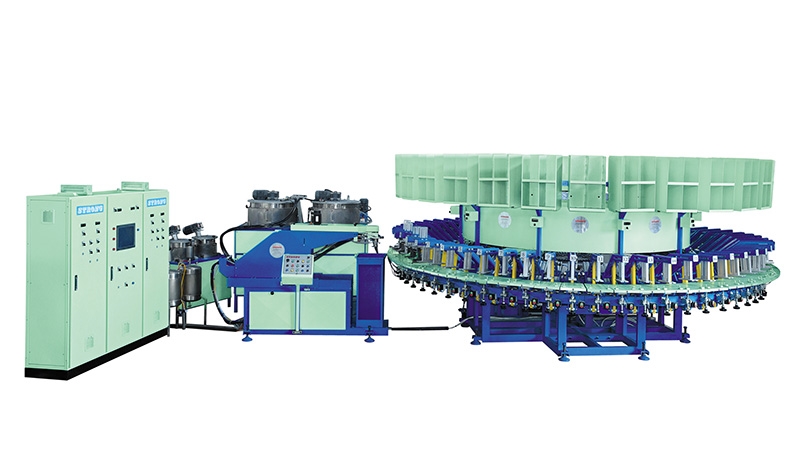

SC-860L1 Full-Automatic Rotary PU Pouring Machine

2.Take automatic design on machanical design,make it to be automatic pouring,materials extruder,mould open and close,nozzle cleaning,etc and save workers for the enterprise.The realization of automatic makes the enterprise in steady development during controlling of producing quality and quantity.

3.During producing,this machine can run in full load,increases producing quantity and its automatic producing can give correct delivery time of products.

4.Using PLC to control machines so that every station can automatically adjust raw materials rate,rotation speed of flow control pump,set temperature of raw materials,controlling pressure and accurately control quality of every product.

5.The rotary speed of mixer head is 9000 r.p.m.,which can save raw meterials,decrease cleaning times.Improve producing efficiency,improve products quantity and decrease producing cost.

6.Using double-layer heating preservation on materials charging bucket that ensure raw materials can work under constant-temperature and save power.

7.Using PID to control barrel heating accurately and ensure that the temperature doesn't change during materisal feeding.

We can make machines according to different requirements of customers.

If you are interested in the above products, please fill out the form below and the relevant personnel will contact you promptly. (Note: Please fill in your information correctly)